A large printing equipment manufacturer sells printing ink machines. After selling the machine, the company does not monitor the performance of the device - specifically the usage of the printing arm and the drive motor.

They would like to be able to capture machine performance information in order to provide remote support, troubleshoot potential issues, and execute repairs.

The manufacturer was looking for a solution for injection printing machine monitoring for both newly manufactured print machines as well as those already in the field, including the location of the equipment.

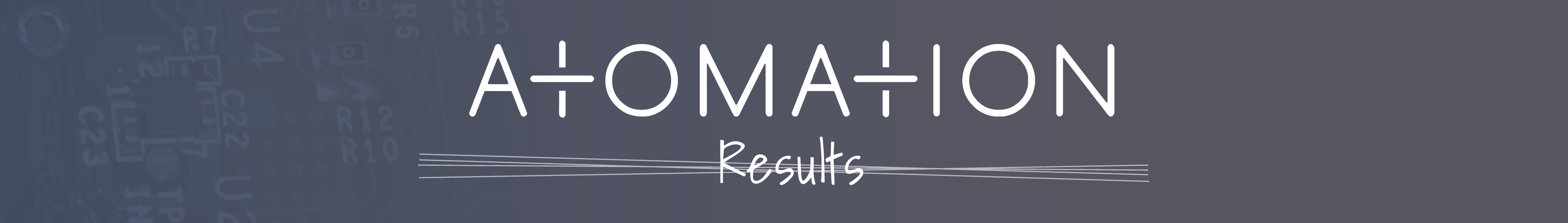

Two AT-C1.0 units were installed on each machine - one on the robot arm and one on the motor - measuring impact, tilt, vibration and temperature.

The gateway was installed inside the machine to upload the data to the cloud and to track the location of the machine itself, giving the manufacturer the specific location of the machine.

Atoms gathered data that the manufacturer had never been able to capture before on customer machine usage. They were also able to compare this data with the operation of new machines and validate operation before shipping newly manufactured equipment.

Bonus: Based on motor and robotic arm usage, the company can now predict when the end-user will run out of ink, giving them an inside track on the next ink sale.

New Insights Yield New Opportunities

Atoms solve challenges previously considered unsolvable. Check out these additional use cases and then contact us to schedule a demo today.