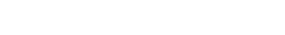

Steel towers in the field are subjected to a wide variety of atmospheric conditions and potential damage. Towers have a variety of sensors that were all measuring separate pieces of data. These sensors also required that an employee visit the tower to download and then analyze the data which was time-consuming and inconvenient, depending on the location of the tower. The manufacturer wanted to know what events and atmospheric conditions were impacting towers and wanted a remote monitoring solution.

Immediate information is needed to quickly correct any

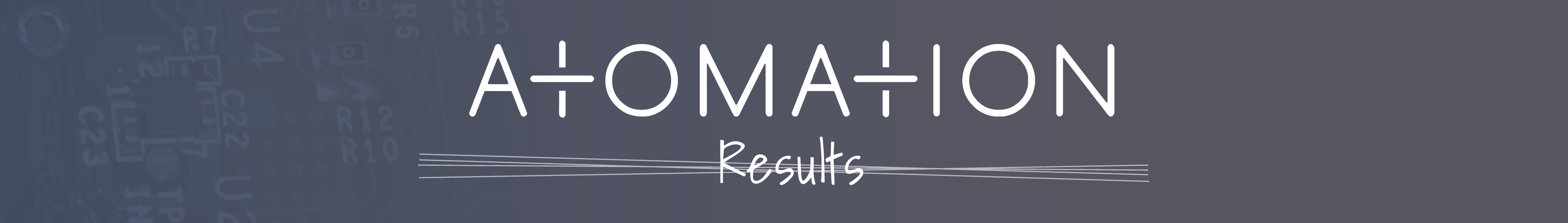

Multiple Atoms were installed at different locations on each individual structure, utilizing wind, vibration, tilt and temperature sensors as well as the ability to detect the presence/absence of EMF. Atomation captured all data points the manufacturer needed and uploaded all data directly to the cloud. No more visiting the towers to download the data!

Installed sensors monitored the following:

- Is there ice or any other weather condition that will damage the tower?

- Is there line galloping?

- Is there arcing?

- During high wind conditions, are the angles or behavior of the arms changing?

- Have the towers or arms been impacted by trees or something else?

- Is there fire in the area?

- Are the wires above the arms energized?

AT-U1.0c Atoms are designed to survive in harsh outdoor environments.

- Atoms were able to predict where a problem was likely to occur based on data captured at the tower.

- Wind and vibration of the towers were also measured and tracked to ensure towers remained balanced.

- Icing was determined by temperature readings below 32 degrees Fahrenheit for more than 24 hours.

- EMF was used to determine if the wires were energized.

- Stand-alone Atoms were attached to the arms of the towers. The standard Atom identifies temperature, line icing range, studying different vibration patterns.

- People resources were more effectively deployed in the field, resulting in better labor management and more efficient triage of possible tower issues.

- Tower issues were identified before outages or issues occurred in the field due to the information Atoms captured and reported to the cloud, giving the manufacturer more information about the stressors impacting towers, improvements to manufacturing and structure and better performance for their customers.

Think Differently About Tower Management

Atoms solve challenges previously considered unsolvable. Check out these additional use cases and then contact us to schedule a demo today.