Limited monitoring options mean that problems with transformers can be difficult to identify and/or predict in the field.

Remote locations, lack of power supply, and the expense of adding a monitoring solution after the transformer has been installed in the field are all reasons why monitoring of this critical piece of equipment has been difficult to accomplish.

Predicting the possible failure of a transformer and the exact location can also be challenging for utilities.

Immediate information is needed to quickly correct any

Transformers will typically signal when problems are about to occur through changes in the average operating temperature or in the vibration signature of the transformer.

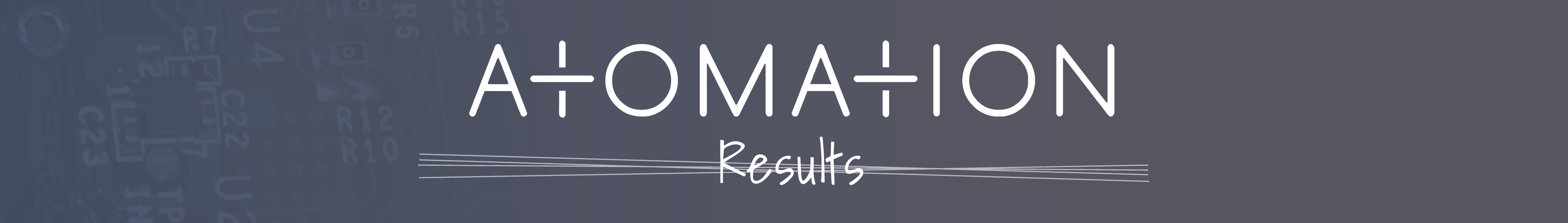

Atoms detect temperature and vibration anomalies making them the perfect solution for this application. Atoms, with the addition of an external current sensor, are also able to capture current spikes and the absence of current.

AT-U1.0c Atoms are designed to survive in harsh outdoor environments.

Atoms were installed on transformers using temperature, impact, and vibration alerts to monitor operations.

The external CT sensor detected the absence of current, giving the team the exact location of the transformer failure. In addition, by sampling the current periodically, teams were able to optimize energy consumption.

Atoms were also able to identify when similar transformers began operating differently, giving maintenance teams the information they needed to proactively maintain overhead and ground transformers.

Solutions for Transformers

Already have transformers in the field? No problem! Atoms are the perfect solution for in-field and legacy equipment. Check out these additional use cases and then contact us to schedule a demo today.